Application areas:

Coal mines, mining, metallurgy, chemical industry, building materials and other industries.

Applicable materials:

Sand and gravel yards, mining, coal mining, concrete mixing stations, dry mortar, power plant desulfurization, quartz sand, etc. Various ores and rocks with feed size ≤ 200mm and grading size of 2mm–70mm.

Working principle:

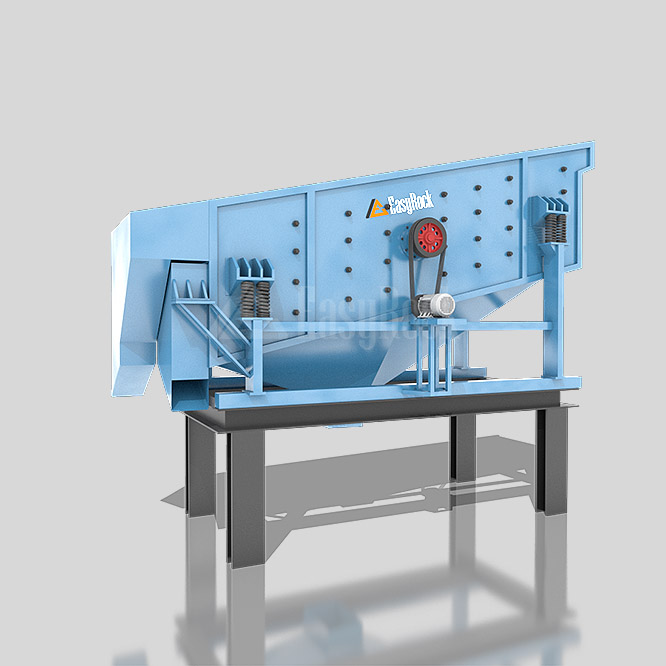

The circular vibrating screen mainly consists of a screen box, screen mesh, vibrator, vibration damping spring device, bottom frame, etc. The motor makes the eccentric block of the vibrator rotate at high speed through the V-belt, which stimulates the screen box to produce a circular motion with a certain amplitude. The material on the screen is subjected to the impulse transmitted by the screen box on the inclined screen surface, and produces a continuous throwing motion. In the process of the material meeting the screen surface, the particles smaller than the screen hole pass through the screen, thereby achieving classification.

Product advantages and selling points:

- Novel structure, large processing capacity, high screening efficiency

- Easy maintenance, using cylindrical eccentric shaft exciter and eccentric block to adjust the amplitude, easy to use and maintain

- Long service life, using spring steel woven screen or punched screen plate, long service life, not easy to block holes

- Low noise, using rubber vibration isolation spring, long service life, low noise, stable resonance area.

Product display:

parameter:

| model | Screen size (mm) | Screen layer number | Screen size (mm) | output(t/h) | power (kW) | Vibration frequency (r/min) |

|---|---|---|---|---|---|---|

| YZS1237 | 3700×1200 | 2.3 | 3-100 | 10-80 | 11 | 750-950 |

| YZS1548 | 4800×1500 | 2.3 | 3-100 | 30-200 | 15 | 750-950 |

| YZS1848 | 4800×1800 | 2.3.4 | 3-100 | 50-250 | 18.5 | 750-950 |

| YZS1860 | 6000×1800 | 2.3.4 | 3-100 | 65-586 | 22 | 750-950 |

| YZS2160 | 6000×2100 | 2.3.4 | 3-100 | 81-720 | 22 | 700-900 |

| YZS2460 | 6000×2400 | 2.3.4 | 3-150 | 100-810 | 30 | 700-900 |