Application areas:

Sand making, mixing stations, artificial sand making, highway pavement stones, mining, metallurgy, refractory materials, cement, coal, glass, ceramics, electricity and other industries.

Applicable materials:

Iron ore, copper ore, gold ore, aluminum ore, manganese ore, lead-zinc ore, river pebbles, granite, limestone, basalt, calcite, barite, dolomite, talc, coal gangue, calcium carbonate, kaolin, bentonite, gypsum, marble and other medium and high hardness materials

Working principle:

The raw ore falls from the feed hopper into the upper crushing chamber onto the upper throwing plate. The material is thrown toward the inner wall of the cylinder by the centrifugal force of the throwing plate. While it collides and crushes with the impact plate on the inner wall, the material falls due to gravity and repeatedly impacts and crushes until it is discharged from the discharge port.

Product advantages and selling points:

The sand output ratio of the first crusher is high, more than 90%

Low investment, high output, the crushing effect is comparable to the impact sand making machine, and the investment is much lower.

Good particle shape, meeting high-standard construction sand

Good crushing fineness, the highest crushing fineness among crushers. The crusher with 6-layer hammer head has a crushing fineness of 0.15-0.12mm, accounting for 40-50%

The hammer head has a gap adjustment device and can be used in reverse, which greatly improves the utilization rate of the hammer head and increases the life by about 5 times.

The distance between the hammer head and the impact plate can be fine-tuned to ensure uniform product particle size.

It is suitable for a wide range of materials and is suitable for crushing medium-hard and extra-hard materials.

Small footprint, easy installation and maintenance

There are two types of hammer heads inside the vertical shaft crusher: fixed hammer heads and movable hammer heads. Equipment selection can be carried out according to user needs. There is a dedicated sales manager to provide you with consultation.

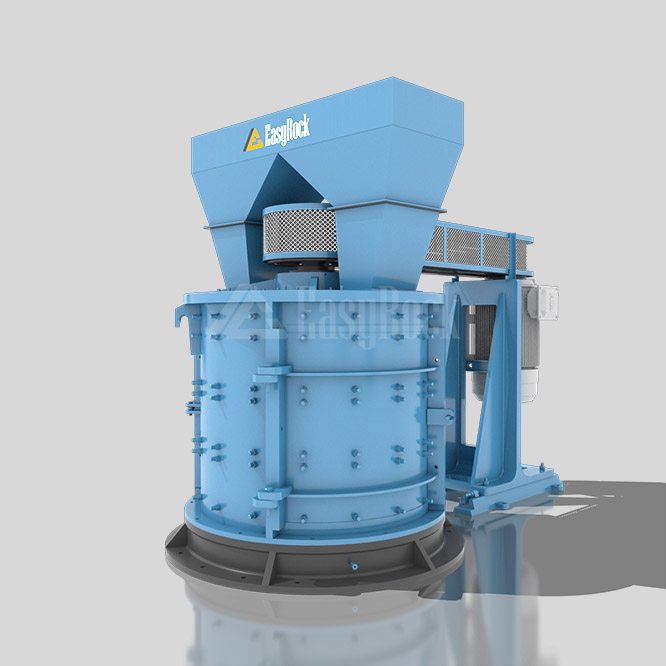

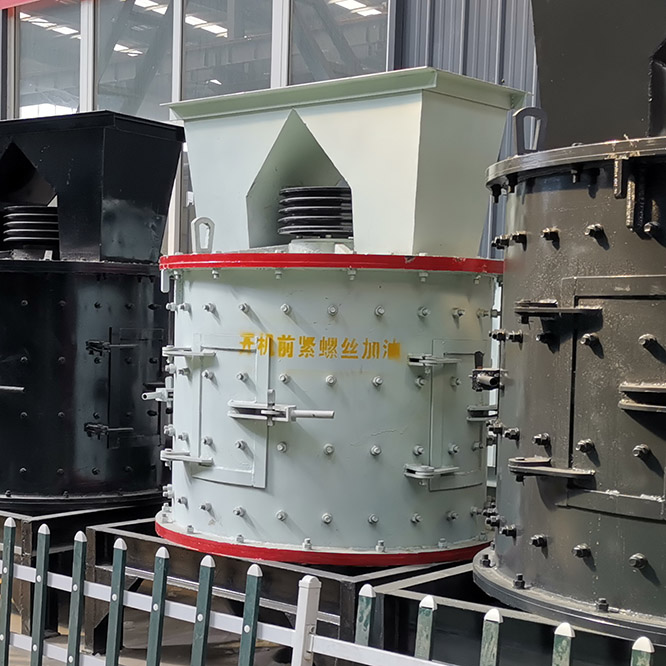

Product display:

parameter:

| model | Cylinder height (mm) | Feed(mm) | output(mm) | output(t/h) | dimensions (mm) | gross weight (t) | power(kw) |

|---|---|---|---|---|---|---|---|

| 800 | 800 | 50 | Materials ≤3mm | 5-15 | 2200×860×1980 | 2.3 | 30 |

| 1000 | 850 | 70 | Materials ≤3mm | 10-30 | 2700×1160×2000 | 4.5 | 55 |

| 1250 | 850 | 100 | Materials ≤3mm | 20-60 | 2800×1400×2730 | 9.73 | 90 |

| 1500 | 1000 | 100 | Materials ≤3mm | 30-80 | 3100×1900×2300 | 18.1 | 110 |

| 1750 | 1410 | 100 | Materials ≤3mm | 40-100 | 3350×2100×2800 | 26.61 | 132 |