Application areas:

Widely used in mining, building materials, metallurgy, chemical industry, domestic waste treatment, construction waste sorting and other industries that require screening

Applicable materials:

Refractory materials, coal, fertilizer, sandstone grading, as well as coal, coke, lime, gold placer, construction waste, and domestic waste.

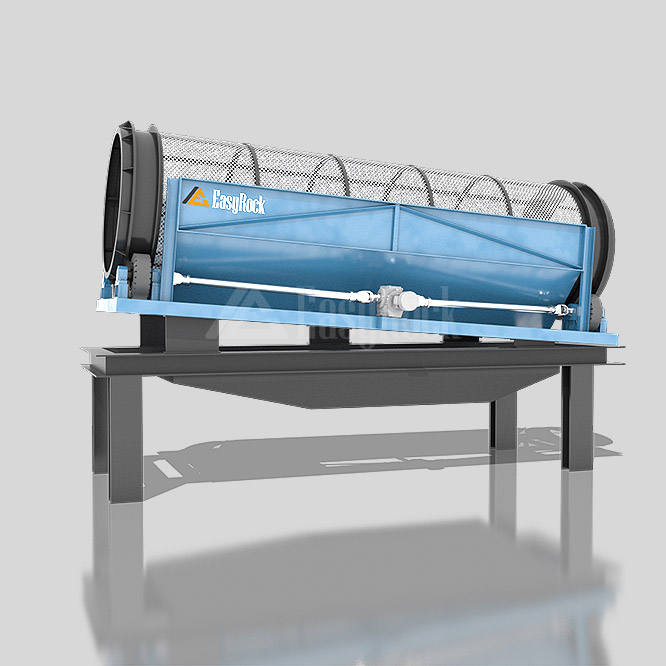

Working principle:

The shaftless drum screen is usually composed of a screen drum, a drum, a reduction motor, a roller support frame, etc. These components work together. The roller drives the drum to rotate. Materials smaller than the screen holes are separated from the screen holes, and materials larger than the screen holes are discharged from the lower end of the drum. The shaftless drum screen completes the screening and grading of materials.

Product advantages and selling points:

- Accurate particle size sorting, with a 2-layer screen design structure, can sort materials at multiple levels, the product on the screen can reach 200mm, the middle of the screen is 20-20mm, and the fine material under the screen can reach less than 5mm.

- Shaftless design, the barrel can screen materials that are easy to entangle, such as ropes and plastic belts.

- Special screen, high screening efficiency and long service life;

- Small installation inclination angle, the screen hole is not easy to be blocked;

- Simple structure and easy maintenance;

- Smooth operation and low noise;

- Small space occupation, convenient for process layout;

- Roller-type power transmission method, small footprint and more stable operation.

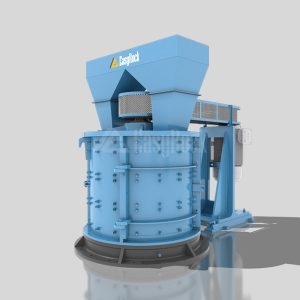

Product display:

parameter:

| parameter | Cylinder Specifications(m) | Speed (r/min) | Screen size(mm) | feed(mm) | output(m³/h) | power(kw) |

|---|---|---|---|---|---|---|

| GTS820 | Φ0.8×2 | 32 | 2-80 | 0-300 | 7-30 | 3 |

| GTS1020 | Φ1×2 | 25 | 2-80 | 0-300 | 10-60 | 4 |

| GTS1230 | Φ1.2×2 | 20 | 2-80 | 0-300 | 12-100 | 5.5 |

| GTS1540 | Φ1.5×4 | 17 | 2-80 | 0-300 | 18-150 | 7.5 |

| GTS1550 | Φ1.5×5 | 17 | 2-80 | 0-300 | 20-180 | 11 |

| GTS1850 | Φ1.8×5 | 14 | 2-80 | 0-300 | 24-220 | 15 |

| GTS2050 | Φ2×5 | 12 | 2-100 | 0-300 | 50-600 | 22 |

| GTS2260 | Φ2.2×6 | 10 | 2-100 | 0-400 | 100-800 | 30 |

| GTS2870 | Φ2.8×7 | 8 | 2-100 | 0-400 | 120-950 | 37 |