Application areas:

Cement plants, quarries, stone factories, coal factories, highway construction, sand and gravel aggregates for roads and bridges, concrete mixing stations, water conservancy projects and other industries.

Applicable materials:

Iron ore, copper ore, gold ore, aluminum ore, manganese ore, lead-zinc ore, river pebbles, granite, limestone, basalt, calcite, barite, dolomite, talc, coal gangue, calcium carbonate, kaolin, bentonite, gypsum, marble and other medium and high hardness materials.

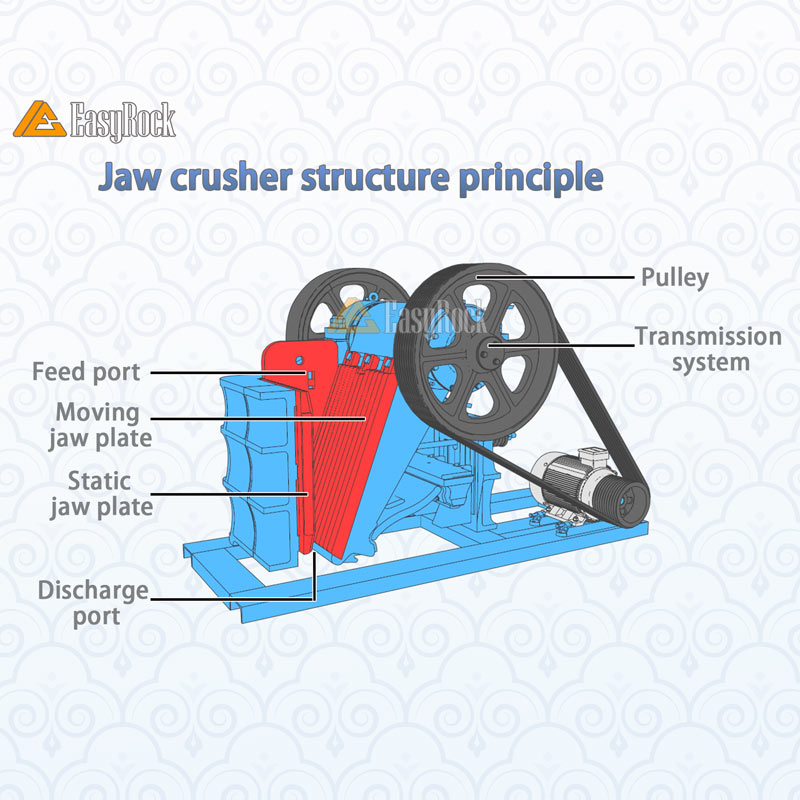

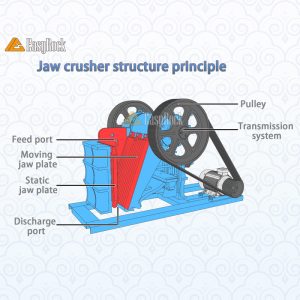

Working principle:

The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate closer to the fixed jaw plate. At the same time, the material is crushed or split to achieve the purpose of crushing; when the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed material is discharged from the lower opening of the crushing chamber.

The jaw crusher is mainly composed of a fixed jaw plate, a movable jaw plate, a frame, upper and lower guard plates, an adjustment seat, a movable jaw pull rod, etc. For real novice users of jaw crushers, it is recommended that when you get the jaw crusher, you must first understand the knowledge of the internal structure of the jaw crusher, so that you will not be clueless and confused when encountering production problems.

Product advantages and selling points:

- The jaw crusher has a simple structure, reliable operation, easy maintenance, economical operating costs, and high production efficiency.

- The “V”-shaped deep cavity crushing has no dead zone, and the material will not be blocked in the crushing chamber, which greatly improves the production efficiency of the equipment.

- The components are highly resistant to pressure and wear. The jaw crusher is made of advanced manufacturing technology and high-wear-resistant materials, making the entire equipment more durable.

- Easy operation and maintenance, simple and rational internal structure design, making the equipment more convenient and quick during use, greatly reducing downtime and maintenance time.

parameter:

| model | Feed(mm) | Output (t/h) | Output ( t/h) | power(kw) | Overall dimensions (mm) |

|---|---|---|---|---|---|

| PE150×250 | ≤130 | 15-45 | 1-4 | 5.5 | 896×745×935 |

| PE250×300 | ≤150 | 15-55 | 3-6 | 7.5 | 1050×987×1000 |

| PE250×400 | ≤210 | 25-60 | 5-20 | 15 | 1215×1520×1030 |

| PE400×600 | ≤350 | 40-90 | 15-60 | 30 | 1650×1588×1050 |

| PE500×750 | ≤425 | 50-100 | 40-110 | 45 | 1956×1918×1920 |

| PE600×900 | ≤500 | 60-125 | 90-180 | 55 | 2250×2733×2280 |

| PE800×900 | ≤600 | 80-140 | 100-220 | 75 | 2450×2950×2490 |

| PE750×1060 | ≤630 | 60-150 | 110-380 | 110 | 2531×2455×2783 |

| PE900×1060 | ≤700 | 100-160 | 230-390 | 110 | 2900×2657×2950 |

| PE900×1200 | ≤750 | 110-165 | 220-450 | 132 | 3100×2760×3260 |

| PE1000x1200 | ≤900 | 110-185 | 315-500 | 132 | 3200x2760x3260 |

| PE1200×1500 | ≤950 | 115-195 | 400-800 | 220 | 3710×3446×4075 |

| PE1500×1800 | ≤1200 | 135-225 | 500-1000 | 280 | 5100×4700×4300 |

| PEX150×750 | ≤120 | 10-40 | 8-25 | 15 | 1310×1118×1145 |

| PEX250×750 | ≤210 | 15-50 | 15-35 | 22 | 1400×1751×1515 |

| PEX350×750 | ≤300 | 15-50 | 18-40 | 30 | 1485×1680×1648 |

| PEX250×1000 | ≤210 | 15-60 | 15-60 | 30 | 1550×1964×1380 |

| PEX250×1200 | ≤210 | 15-60 | 20-60 | 37 | 1530×1946×1380 |

| PEX300×1300 | ≤250 | 25-60 | 16-105 | 55-75 | 2000×2320×1730 |