Application areas:

Bridge construction, metallurgy, mining, cement, chemical industry and other industrial sectors, highways, water conservancy projects, construction projects and other fields.

Applicable materials:

Limestone, gypsum, silica, barite, feldspar, calcite, dolomite, talc, graphite and other mineral and rock materials with a compression resistance not exceeding 300Mpa and a surface moisture content not exceeding 8%-10%.

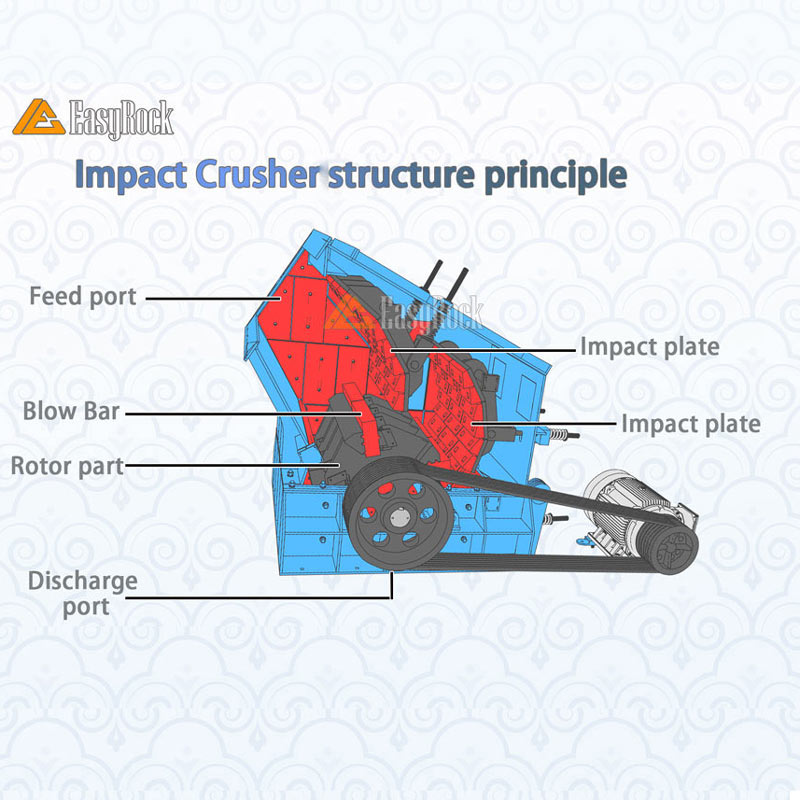

Working principle:

The impact crusher is a machine that uses impact energy to crush materials. The motor drives the rotor to rotate at high speed, and the material is crushed by the high-speed impact of the plate hammer, and then it is crushed again on the impact plate, and then bounces back from the impact plate to the plate hammer and is crushed again. The plate hammer hits the impact plate repeatedly until the material is crushed to the required particle size and discharged from the discharge port. The size and shape of the material can be changed by adjusting the gap between the impact frame and the rotor.

Product advantages and selling points:

- The sturdy heavy-duty rotor structure improves the equipment’s processing capacity and crushing ratio; the high-quality welded structure ensures that the machine can withstand large impacts and achieve good crushing effects.

- The reliable locking structure of the plate hammer has good impact resistance and wear resistance and maintains stable discharge particle size.

- The large-scale use of new high-wear-resistant materials reduces the wear of wear parts, extends the replacement cycle, and saves costs.

- Hydraulic cover opening and hydraulic auxiliary adjustment of the gap between the impact plate and the plate hammer shorten downtime.

- The equipment is equipped with a variety of safety locking devices to improve safety performance while reducing labor intensity.

- The optional third impact frame makes the product particle shape more beautiful.

Product display:

parameter:

| model | Feed(mm) | Feed size (mm) | output(t/h) | Power(w) | Dimensions (mm) |

|---|---|---|---|---|---|

| PF-1007 | 400 x 730 | ≤250 | 15-60 | 45 | 2319 x 1654 x 2558 |

| PF-1010 | 400 x 1080 | ≤300 | 50-90 | 55 | 2319 x 2001 x 2558 |

| PF-1210 | 450 x 1060 | ≤300 | 80-150 | 90 | 2585 x 2053 x 2809 |

| PF-1214 | 450 x 1440 | ≤300 | 100-200 | 132 | 2582 x 2403 x 2809 |

| PF-1315 | 550 x 1530 | ≤350 | 130-280 | 160 | 2930 x 2761 x 3053 |

| PF-1320 | 610 x 1900 | ≤500 | 180-400 | 220 | 3224 x 3175 x 2706 |

| PF-1520 | 830 x 2040 | ≤700 | 300-550 | 315-400 | 3959 x 3564 x 3330 |

| PF-1820 | 1260 x 2040 | ≤800 | 600-800 | 630-710 | 4400 x 3866 x 4009 |

| PFV-1210 | 450 x 1060 | ≤300 | 80-150 | 90 | 2582 x 2053 x 2809 |

| PFV-1214 | 450 x 1440 | ≤300 | 100-200 | 132 | 2582 x 2403 x 2809 |

| PFV-1315 | 550 x 1530 | ≤350 | 130-280 | 185 | 2930 x 2761 x 3053 |

| PFV-1320 | 610 x 1900 | ≤500 | 180-400 | 250 | 3224 x 3175 x 2706 |