Application areas:

Sand and gravel yards, fine crushing of cement plants, mining, coal mining, concrete mixing plants, dry mortar, desulfurization of power plants, quartz sand, etc.

Applicable materials:

Bluestone, silica, river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Working principle:

The main working part of the hydraulic open-box sand making machine is a fixed plate hammer structure. The material enters the cavity and is repeatedly hit between the plate hammer and the impact plate. It is crushed by the impact, impact, shearing and grinding of the high-speed moving plate hammer. There is a screen plate at the bottom of the rotor. The particles smaller than the size of the screen hole in the crushed material are discharged through the screen plate, and the coarse particles larger than the size of the screen hole are retained on the screen plate and continue to be hit and ground by the hammer, and finally discharged out of the machine through the screen plate.

Product advantages and selling points:

High crushing ratio, can directly feed large pieces of material (within 30cm), the size of the discharge material is adjustable, and it is formed in one go.

Fixed plate hammer structure, greater crushing impact force.

Simple and practical structure, simple operation, convenient maintenance,

High fine crushing efficiency, low power consumption, high output, low energy consumption.

Added a full set of hydraulic unpacking system, one-button opening of the machine cavity, convenient replacement of hammer head and liner, maintenance and repair, and more labor-saving operation.

The discharge particle size is controllable, the particle shape is regular, and the required material particle size can reach more than 95%.

Easy to use and can be adjusted at will. The adjustment plate can be turned over at both ends, the life is increased, and the adjustment is easier.

Low loss and long life. The hammer head can be used on all four sides, with high utilization rate and high hardness.

The product is widely applicable, cost-effective, and has a short investment recovery period.

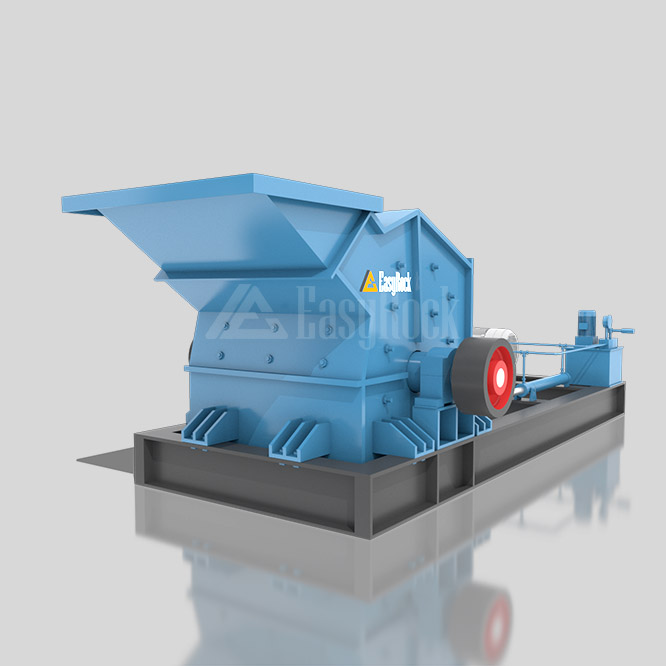

Product display

parameter:

| model | feed(mm) | output(mm) | Discharge gap adjustment width (mm) | Output (t/h) | power (kw) |

|---|---|---|---|---|---|

| PXJ800×400 | <120 | <5 | 5-20 | 20-45 | 37-45 |

| PXJ 800×600 | <180 | <5 | 5-20 | 35-55 | 45-55 |

| PXJ 800×800 | <180 | <5 | 5-20 | 35-65 | 45-55 |

| PXJ 1010×1010 | <180 | <5 | 5-20 | 45-75 | 55-75 |

| PXJ 1200×1000 | <180 | <5 | 5-20 | 70-110 | 90-110 |

| PXJ 1200×1200 | <180 | <5 | 5-20 | 90-120 | 110-132 |

| PXJ 1400×1400 | <190 | <5 | 5-20 | 100-150 | 160 |

| PXJ 1600×1600 | <190 | <5 | 5-20 | 170-250 | 250 |

| PXJ 1800×1800 | <190 | <5 | 5-20 | 250-310 | 315 |