Application areas:

Applied in railway, highway, cement, building materials, refractory, ceramics, chemical industry and other industries.

Applicable materials:

Gypsum, alum, bricks, tiles, limestone, bluestone, coal, and other brittle minerals.

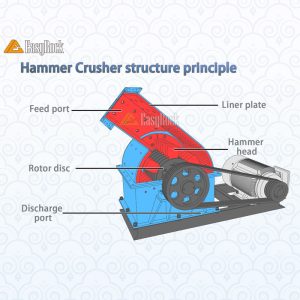

Working principle:

The main working part of the hammer crusher is the rotor with hammer head, which is composed of main shaft, disc, pin shaft and hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port and crushed by the impact, impact, shearing and grinding of the high-speed hammer. There is a screen plate at the bottom of the rotor. The particles smaller than the size of the screen hole in the crushed material are discharged through the screen plate, and the coarse particles larger than the size of the screen hole are retained on the screen plate and continue to be hit and ground by the hammer, and finally discharged from the machine through the screen plate.

Product advantages and selling points:

- The machine has large feed size and high crushing ratio.

- Low energy consumption, high cost performance and low investment.

- Simple and practical structure, easy to maintain.

- The output size can be adjusted according to different needs

- Fine processing of good materials.

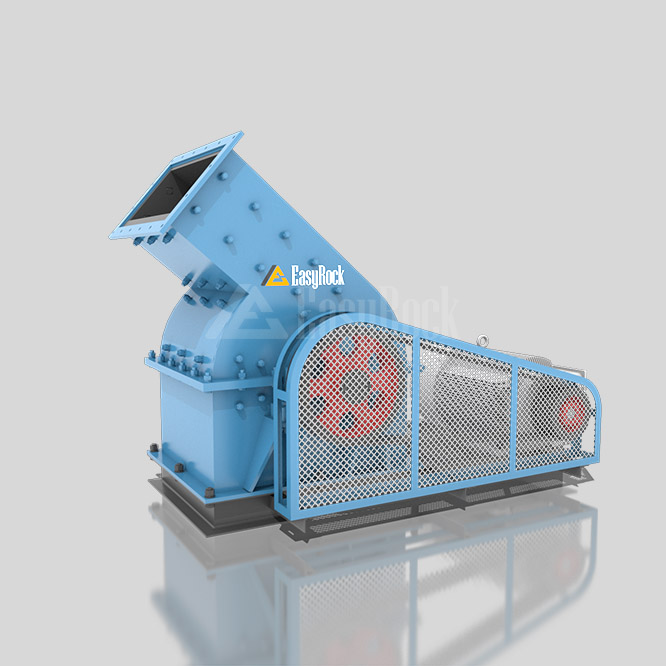

Product display:

parameter:

| model | feed (mm) | Output (mm) | Output (t/h) | Power (kw) | Weight(t) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| PCФ350×260 | <150 | <25 | 1-2 | 5.5 | 0.2 | 900 × 550 × 700 |

| PCФ400×300 | <200 | <25 | 5-10 | 11 | 0.8 | 900 × 670 × 860 |

| PCФ600×400 | <250 | <30 | 10-22 | 22 | 2.26 | 1200 × 1050 × 1200 |

| PCФ800×600 | <250 | <35 | 18-40 | 55 | 4.8 | 1310 × 1180 × 1310 |

| PCФ1000×800 | <350 | <35 | 25-50 | 75 | 5.9 | 1600 × 1390 × 1575 |

| PCФ1000×1000 | <350 | <35 | 30-55 | 90 | 8 | 1800 × 1590 × 1775 |