Application areas:

construction, brick making industry, metallurgy, mining, ceramics, refractory materials, chemicals, highways, railways, concrete mixing stations, dry mortar, sand and gravel yards, mineral processing and other industries.

Applicable materials:

Suitable for crushing more than 300 kinds of materials such as coal slag, slag, shale, coal gangue, construction waste, and building waste from brick and tile factories; bluestone, iron ore, marble, granite, basalt, quartz, slag, slag stone and other medium hardness and wet material crushing.

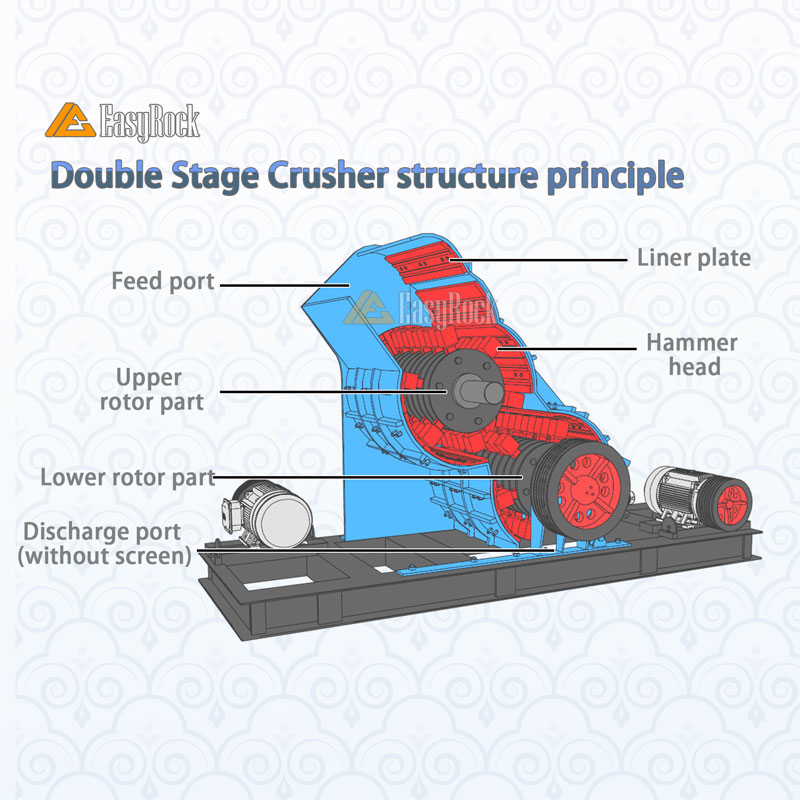

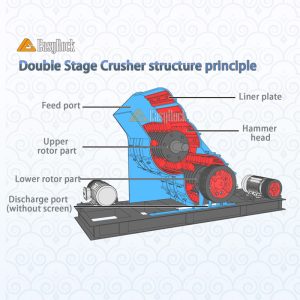

Working principle:

The cavity structure of the double-stage crusher consists of two sets of rotors, which is equivalent to two crushers in one.

After the material is crushed by the upper hammer, it is immediately crushed again by the lower hammer.

The materials collide with each other and crush, forming the effect of hammer hitting material and material hitting material.

Product advantages:

- High fine powder ratio of discharge.

- Can handle wet materials (moisture content less than 25%) without clogging.

- Hammer head gap adjustment design, higher hammer head utilization rate.

- Hydraulic start casing.

- Can directly feed large materials, high crushing ratio.

- Simple and easy to operate and maintain

Output of double-stage crusher

Under normal circumstances, the output of different models and sizes is about 5t-200t. The output of the crusher is related to the hardness of the raw material, the size of the feed particle size, and the fineness of the crushing. The smaller the feed particle size, the higher the output. The larger the feed particle size, the smaller the output. The higher the hardness of the feed raw material, the smaller the output; the lower the hardness, the greater the output. The coarser the crushing fineness requirement, the higher the output; the lower the crushing fineness requirement, the lower the output

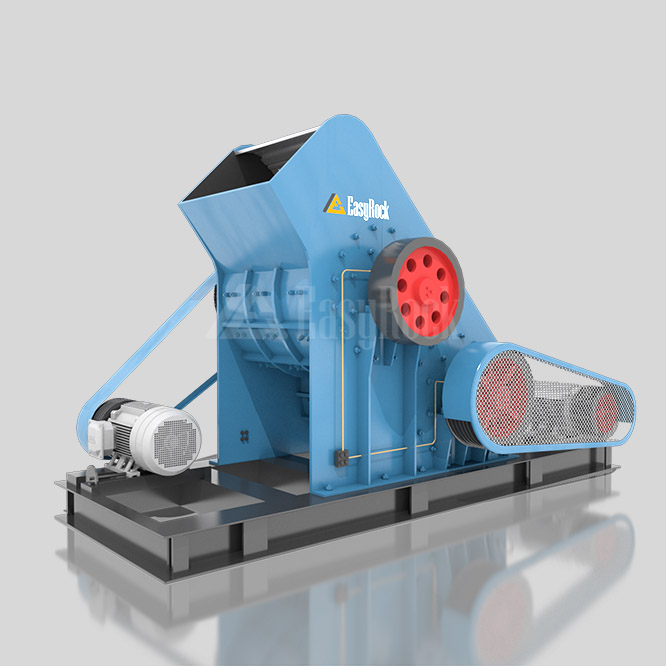

Product display:

parameter:

| model | Output(t/h) | Power (kw) | Maximum feed size (mm) | Output particle size | Overall dimensions (m) | Hammer head Material | Lining board | Thickness of outer shell steel plate (mm) | Moisture content |

|---|---|---|---|---|---|---|---|---|---|

| 600*400 | 15-20 | 18.5+15 | 150 | ≤3mm | 2560×1020×1650 | Forging | Material | 12 | < 20% |

| 600*600 | 20-25 | 18.5+18.5 | 150 | ≤3mm | 2750×1280×1750 | Forging | Manganese 13 | 12 | < 20% |

| 700*700 | 25-30 | 22+22 | 150 | ≤3mm | 2850×1060×1780 | Forging | Manganese 13 | 14 | < 20% |

| 800*600 | 35-45 | 45+37 | 200 | ≤3mm | 3760×1340×2140 | Forging/cast steel | Manganese 13 | 20 | < 20% |

| 800*800 | 45-55 | 55+55 | 230 | ≤3mm | 3750×1800×2150 | Forging/cast steel | Manganese 13 | 20 | < 20% |

| 1000*900 | 60-70 | 75+75 | 300 | ≤3mm | 4500×1700×2750 | Alloy | Manganese 13 | 25 | < 20% |

| 1100*1000 | 70-100 | 110+90 | 320 | ≤3mm | 4800×2050×2950 | Alloy | Manganese 13 | 30/25 | < 20% |

| 1200*1000 | 90-130 | 132+110 | 320 | ≤3mm | 4750×2560×3550 | High chromium alloy | Manganese 13 | 30/25 | < 20% |

| 1400*1200 | 130-160 | 160+132 | 400 | ≤3mm | 5100×2750×3700 | High chromium alloy | Manganese 13 | 40 | < 20% |

| 1600*1400 | 150-200 | 200+200 | 450 | ≤3mm | 5280×2850×3800 | High chromium alloy | Manganese 13 | 40 | < 20% |

| 1800*1600 | 300-350 | 260+260 | 550 | ≤3mm | 5980×3250×4200 | Forging | Manganese 13 | 50 | < 20% |