Application areas:

Especially suitable for crushing materials used in construction, highways, mines, stone factories, coal mines, building materials, chemicals, and metallurgical industries

Applicable materials:

Construction waste, building waste, limestone, barite, sandstone, slag, slag, shale, gangue, bluestone, iron ore, marble, quartz, slag, slag stone and other medium and low hardness materials.

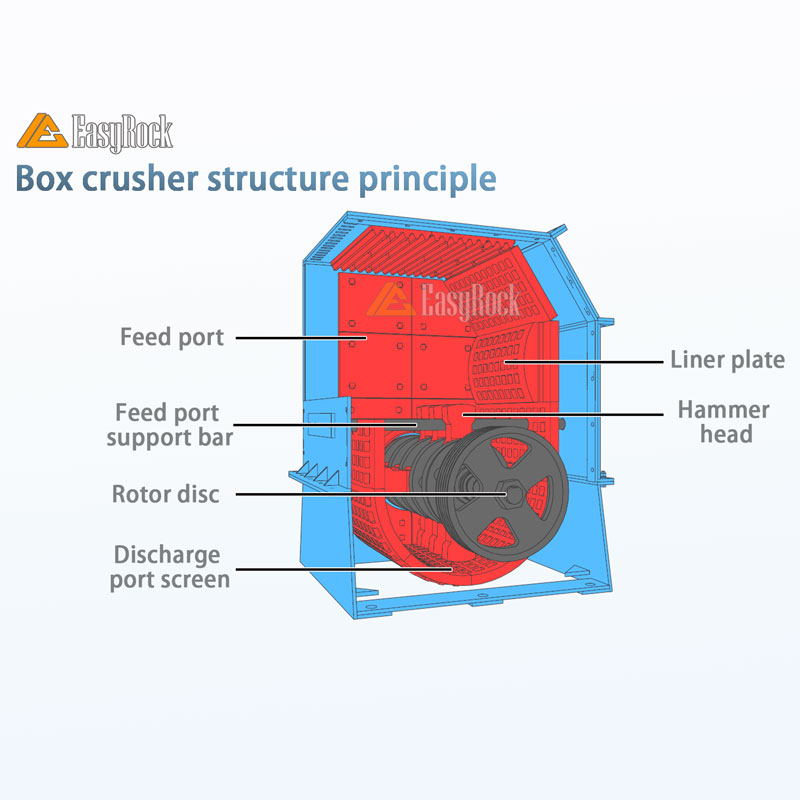

Working principle:

The rotor disc, driven by the motor, drives the hammer to make high-speed circular motion. When the material enters the crushing chamber, the large pieces of material are piled on the middle bars specially designed in the machine. After being crushed, the large pieces of material are smaller than the gap between the bars and enter the crushing chamber for further crushing, so that the coarse and medium crushing can be completed in one step, and finally the materials that meet the requirements are discharged through the sieve holes.

From the appearance, the box crusher looks like a big box, which is also the origin of its name. Because the feed inlet is large, in order to prevent the stone from flying out of the machine, a steel chain is used as a shield, which can prevent the crushed stone from splashing out. Adding an iron chain will not hinder the feed and prevent splashing, which is really useful.

Product advantages and selling points:

- The machine has large input particle size, small output particle size, good particle shape, and one-step coarse and medium crushing. The process is simplified, and the low-cost operation of one crushing and two crushing is completely realized. It can reduce 40% of the cost, low energy consumption, and low investment.

- The single hammer head has a large mass and a large moment of inertia, which overcomes the weaknesses of other hammer crushers, such as fast wear of the hammer head and high loss of wearing parts. It has the characteristics of high crushing ratio of feed particle size and low maintenance cost.

- The hammer shaft of the box crusher can be installed adjustable, and the hammer head has a long life.

- The size of the discharge screen is adjustable, the product particle size is controllable, and the particle shape is good.

- The box crusher chassis can be turned over, which is more convenient for maintenance.

- Square handle bolts are impact-resistant and wear-resistant.

- High output and stable performance.

- The hammer head, grate plate and impact plate are made of high wear-resistant materials, which have a longer service life.

- The matching power is small, the energy consumption is low, the maintenance is simple, and there are few wearing parts.

Product display:

parameter:

| model | feed (mm) | For stone | Output (t/h) | Power (kw) |

|---|---|---|---|---|

| 600×600 | ≤400 | Pressure<300MPa | 20-30 | 30-37 |

| 800×800 | ≤450 | Pressure<300MPa | 40-70 | 45-55 |

| 700×1000 | ≤500 | Pressure<300MPa | 50-80 | 45-55 |

| 900×1200 | ≤800 | Pressure<300MPa | 70-100 | 75-90 |

| 1000×1000 | ≤800 | Pressure<300MPa | 90-120 | 75-90 |

| 1200×1200 | ≤900 | Pressure<300MPa | 130-160 | 110-132 |

| 1400×1400 | ≤1000 | Pressure<300MPa | 190-210 | 132-160 |

| 1600×1600 | ≤1000 | Pressure<300MPa | 250-300 | 160-210 |

| 1800×1800 | ≤1200 | Pressure<300MPa | 300-400 | 210-280 |